Industry-Specific Requirements for Personal Protective Equipment Explained

It has become pertinent to note that the use of requirements for personal protective equipment in the present-day world cannot be overemphasized. As they know the importance of protection in a high-risk industrial setting a busy medical facility or even in day-to-day usage, they need to identify and use appropriate PPE. As we will see in this guide, PPE comes in many forms and uses since it plays a critical role in achieving health and safety standards in different production sectors.

Why PPE Matters?

Wherever chemicals or possible hazards are present, the correct protective clothing can easily be the decisive factor between life and death at the workplace. For this reason, appropriate PPE not only shields a person from physical impairment but also toxic chemicals as well as possible sickness. PPE is an important element of protecting people at work or in certain industries to address safety requirements contained within the regulations on occupational safety.

In the UK post code often define areas with specific safety regulations or requirements for industries handling hazardous materials. Employers need to ensure they comply with location-specific guidelines, as these can influence the type of PPE necessary for different environments. Purchasing suitable PPE not only minimizes risks to employees’ lives but also increases efficiency and organization output due to a decrease in the number of instances where employees are unable to work as a result of an injury.

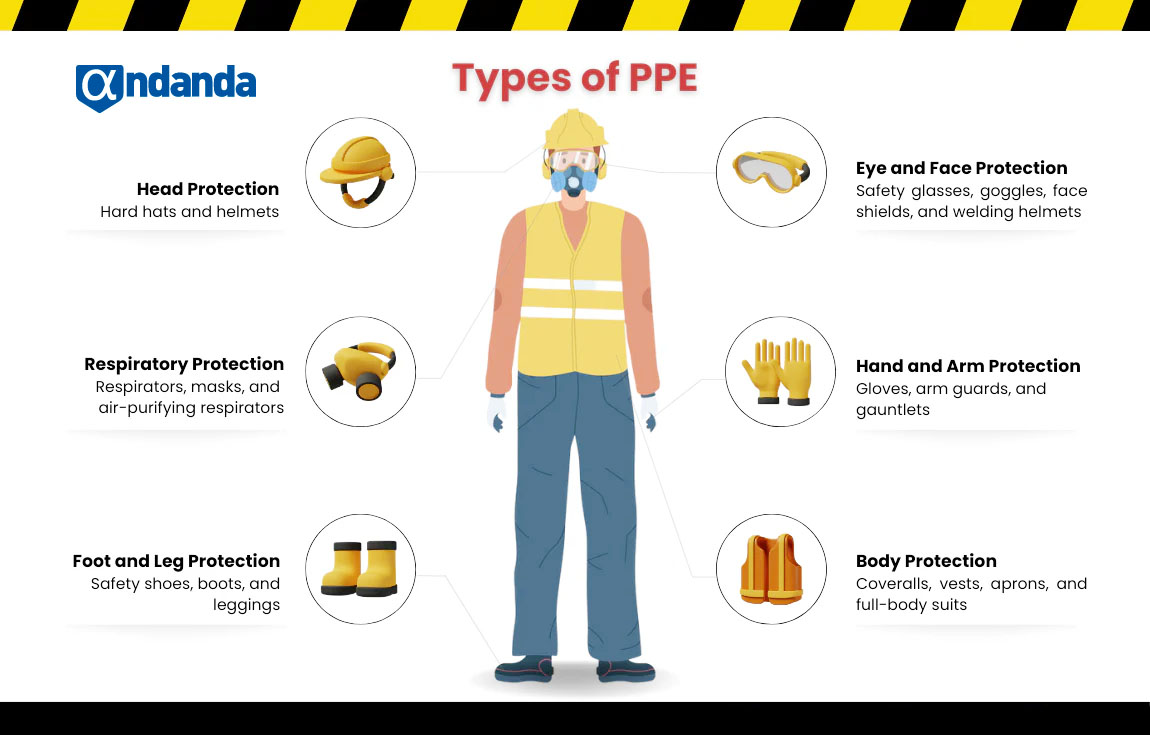

Categories of PPE:

Different categories of PPE are available for use and therefore it is important to understand each type to choose appropriately. Here’s a breakdown of various PPE categories:

Respiratory Protection

Respirators are important when it comes to protection against some substances which may be inhaled.

• Respiratory Masks: These masks help to screen out the contaminants in the air, hence making the air that one breathes to be clean and safe.

• Respirators: These afford more protection and can be applied where risky respiratory conditions are present.

• Face Shields: They supplement protection of the face especially where there are splashes of chemicals or bits of debris flying around.

Eye Protection

They also add that guarding your eyes against risks is very important. Common types of eye protection include:

• Safety Glasses: These offer rudimentary impact and dust‒repellent properties in much the same manner as the former examples.

• Safety Goggles: They provide a better secure hold and also protection from liquid splashes and dust as compared to the previous one.

Hand Protection

It was observed that hands are very vulnerable to different risks and proper hand protection is required. Types include:

• Gloves: It is worn in different types including disposable gloves, nitrile gloves as well as latex gloves, all of which have different characteristics.

• Disposable Gloves: Best used for short-term purposes and when in contact with some contaminants.

• Nitrile Gloves: Chemical and puncture-proof, and have good solidity.

• Latex Gloves: Are versatile but may provide a tight fit and some are likely to develop an allergy to latex.

Protective Clothing

Covering the body with appropriate clothing protects against various hazards:

• Coveralls: These give full body coverage and are used in dangerous areas.

• Lab Coats: Effectively protects against spilling and splashing hence is often used in Laboratories.

• Boots/Safety Footwear: These are used to shield feet from weights, sharp implements, and anything that might be dangerous to the feet.

General PPE Requirements by Different Industry User Repository

Healthcare Sector

In healthcare facilities, there is always a necessity to wear requirements for personal protective equipment which is essential in the prevention of medical workers from pathogens and toxic materials. This Personal Protective Equipment includes Gloves, Face masks or shields, protective goggles or face shield protectants, and protective gowns. These include medical products that assist in avoiding the spread of diseases, cleanliness, as well as safety while handling patients or during specific medical procedures.

Construction Industry

The construction industry requires high levels of PPE due to the nature of places that are under construction which pose a lot of dangers to the workers. Some of the indispensable tools for use are headgear for protection against falling items, glasses to protect eyes from several flying objects, and ear protectors in the form of plugs or earmuffs to protect the ears from high-pitched noise, and the steel capped shoes to protect the feet from impacts from falling or rolling objects.

Manufacturing Sector

In manufacturing settings, requirements for personal protective equipment are critical in preventing employees from being at risk of injury from operating equipment or being in contact with toxic compounds. Other protective gears include ear protection including plugs and muffs that reduce the effects of loud noise from operating tools and machinery; safety goggles to protect the eyes from accidental contact with dust and debris, hard hatted to protect the head from impact and or falling objects and lastly breathing masks that filter the air one breathes in from dangers substances in the environment such as toxic fumes.

Agricultural Field

Since agricultural employees toil in different environments, they are at high risk of getting exposed to chemicals and physical hazards. Some of the precautionary measures that are standard in mines involve wearing of uniform, gloves, caps that cover most parts of the head to cover from the sun, and strongly built boots that protect feet from thorny plants and from any hard surfaces. It is important to understand that respirators are perhaps the best ways of protecting oneself against the effects resulting from the inhalation of dangerous chemicals such as pesticides.

Laboratory Environment

In medical laboratories, PPE is essential in shielding the personnel from possible chemical and biological agents as well as from other laboratory hazards. Regalia includes; aprons to shield clothes and the skin, safety glasses to shield the eyes, and gloves to protect the hands from chemicals, face masks. Additionally from handling particular substances that are rated to be more hazardous, special respirators may be required.

Emergency Response Services

Firefighters and paramedics are some of the employees who need to use PPE in high-risk/pressure incidents. This includes flame-resistant apparel to protect against heat and flame, headgear to protect the head, appropriate footwear for specific environments, and respiratory protective equipment to protect against hazardous gases and fumes.

Key Considerations When Choosing PPE

Choosing the right PPE involves several factors:

Risk Assessment: PPE depends on the nature and type of risk that is prevailing to one or to the working environment one is exposed to.

Comfort and Fit: It is also important to check that the PPE makes a tight coverage on the wearer, but is also comfortable because a gear that fits loosely will be less effective and will not be worn by the wearer.

Compliance with Standards: Ensure that your PPE has been tested and certified to meet certain standard safety specifications and requirements including the following.

Training: It is important to train individuals on the proper usage and management of PPE for the equipment’s protection to hold worth.

Ensuring Safety Equipment Integrity through Regular Maintenance and Inspection

The reporting of damaged or faulty PPE equipment should probably also have clear procedures that should also be adhered to. It is also important that all the personnel understand that they should report any problems with their equipment as soon as they arise. It leads to frequent and quick repairs or replacements of the machinery to minimize interruption thus eliminating risks. Thus, by adhering to and developing the procedures for submitting reports, you positively affect a decrease in the risks of the employees’ exposure to hazardous conditions and increase the credibility of the workplace.

Where to Buy PPE?

When purchasing PPE, consider reputable suppliers who offer high-quality products. For a comprehensive selection of PPE, visit Andanda for various options, including disposable masks, industrial safety gloves, and FDA-approved face shields.

Conclusion

Personal Protective Equipment (PPE) is more than just gear; it’s a crucial component of workplace safety and health. By understanding the different types of PPE, industry-specific needs, and proper maintenance practices, you can make informed decisions to protect yourself and others. For high-quality PPE solutions, visit Andanda and ensure you’re equipped to handle any challenges safely. By following these guidelines and utilizing the right PPE, you can contribute to a safer and healthier environment in any setting. Stay protected and stay safe!