Basic Information

Product Description

Application

SIZE SPECIFICATION

Basic Information

| Product name | Flyther high cut waterproof safety boots |

| Item No. | 106905 |

| SKU | AE0707061-AE0707072,AE0707074 |

| European Size | 36-48 |

| Package | 1 pair/box ; 4 boxes/carton |

| Carton size | 36-42:49*30*36cm, 43-48:53*32*40cm |

| Product standards | EN ISO 20345:2022 WPA SR, ASTM F2413-18 M/I/C PR SD100 |

| Characteristics | anti-smash/ anti-static/ waterproof puncture-resistant / SR slip-resistant |

Product Description

- Flyther high cut waterproof safety boots are equipped with the top-tier Crazy-Horse Leather upper, steel toe cap, and PU+ rubber outsole. These features ensure exceptional performance in waterproofing, anti-static protection, anti-smash capabilities, puncture resistance, slip resistance, and abrasion resistance,making it an ideal choice for wear.

Feature

- the top-tier Crazy-Horse Leather upper offers exceptional waterproofing abrasion resistance, ensuring breathability and comfort. The heel is reinforced with double layers of stone grain leather, which extends its service life.

- The PU+ rubber outsole offers SR slip-resistance, corrosion resistance, and ensures safe and comfortable walking.

- The toe is wrapped in steel cap to prevent heavy objects from falling off during work and ensure work safety.

Application

It is suitable for flat surfaces, areas with puncture risk, dry environments, and other scenarios.

Industries

Suitable for automobiles, construction, manufacturing, logistics, warehousing , etc.

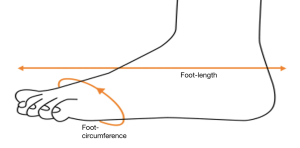

SIZE SPECIFICATION

| Sizing Chart | |||||||||||||||

| CHN | 34 | 35 | 36 | 37 | 38 | 39 | 40 | 41 | 42 | 43 | 44 | 45 | 46 | 47 | 48 |

| EUR | 35 | 35.5 | 36.5 | 37 | 38 | 38.5 | 39.5 | 40 | 41 | 41.5 | 42.5 | 43 | 44 | 44.5 | 45.5 |

| USA | 4 | 4.5 | 5 | 5.5 | 6.5 | 7 | 7.5 | 8 | 8.5 | 9.5 | 10 | 10.5 | 11 | 11.5 | 12 |

| Foot Length

(mm) |

220 | 225 | 230 | 235 | 240 | 245 | 250 | 255 | 260 | 265 | 270 | 275 | 280 | 285 | 290 |

| Note: The correct posture must be adopted during measurement: stand in parallel (do not sit, do not squat), and the weight is divided into both feet. | |||||||||||||||

Notes:

① The feet are basically symmetrical, and the data of a larger foot should be prevailing;

② When the instep is high and the foot is wide, it is recommended to choose a size larger; When the instep is flat and the foot is thin, it is recommended to choose a size smaller;

③ Size data is for reference only, and it is subject to personal wear experience.

Use Instructions

- Anti-static shoes must be used if the build-up of static electricity must be minimized by dissipating static charges, thereby avoiding the risk of ignition of flammable substances and vapors, and if the risk of electric shock from any motor or live parts is not eliminated. However, it is important to note that anti-static shoes merely add a resistance between the foot and the ground and do not guarantee adequate protection against electric shock. If the risk of electric shock is not completely removed, other measures should be taken to avoid this risk. Such measures, like the additional tests mentioned below, should be a routine part of workplace accident prevention procedures.

- Experience has shown that for shoes used for anti-static purposes, the discharge path through the product should have a resistance of less than 1000 MΩ over its full service life. In the event of any circuit failure at voltages up to 250 V, to ensure a degree of protection against the risk of electric shock or ignition at the same time, the minimum limit of resistance for new shoes is 100 KΩ. However, in some cases, it should be clear to the user that the shoe will not provide adequate protection, so additional measures should always be taken to protect the wearer.

- The resistance of such shoes can change significantly due to bending, contamination or moisture. Some products will not perform their intended function if worn in wet conditions. To ensure that the product fulfills its designed function of dissipating electrical charge throughout its service life and to provide some protection at the same time, it is recommended that the user establish a testing mechanism for the resistance of the shoe and have it tested on a regular basis.

- If the use cycle is extended, Class I shoes will conduct electricity due to lower resistance caused by moisture absorption.

- If the sole material is susceptible to contamination during use, the wearer should check the resistance value of the shoe each time before entering a hazardous area.

- In places where anti-static shoes are used, the ground resistance should not cause the protective function of the shoes to fail.

- During use, there should be no insulating parts between the foot and the insole of the shoe. If there is an insole between shoe inserts and the foot, the overall resistance value of the shoe/insole should be checked.

Warning

- This product comes with a pair of removable insoles that have been tested as part of the shoe, so the insoles should be used with the shoe and should not be replaced with other materials, as this will affect the protective performance of the shoe. If replacement is required please use the same type of insole provided by the manufacturer instead.

- The test(WRU) of water permeability and water absorption of the upper involves only the upper material and does not guarantee the overall waterproofness of the shoe seal.

- Whether this safety shoe can be used in conjunction with other safety protection products (safety pants and leggings) should be judged by the user in order to avoid safety risks during use.

Use Limitations

- This product is not resistant to strong acids and alkalis, and is not suitable for use in places with corrosive media such as chemicals that are often in contact with them.

- This product can not be used in high temperature and water environment for a long time, otherwise it will seriously affect its service life, and may even deglue and break the bottom.

Storage

- The product should be stored in the original packaging and placed in a cool, dry, freeze-proof and light-proof place to avoid the presence of high-power electric field and power generation equipment in the storage environment.

Maintenance

- Clean safety shoes regularly, but solvents should not be used as cleaning agents, while direct rinsing with water should be avoided.

- Use a soft brush or slightly damp rag to remove dust and dirt from the shoes when cleaning, then dry in a ventilated place.

- Please oil and maintain the leather frequently to prevent cracking and aging.