View3000: Anti-Scratch Goggles for Superior Eye Protection

Eye protection is essential in industries exposed to hazards like flying debris, chemical splashes, or intense light. The View3000 Anti-Scratch Goggles prioritize safety and comfort with a full transparent frame providing 360-degree vision for unobstructed views. Engineered for durability, they resist surface scratches while maintaining clarity in challenging environments. Weighing just 46g due to their lightweight material, these goggles ensure minimal wearer fatigue during extended wear. Combining functionality and comfort, they are indispensable protective gear across diverse industrial sectors.

Importance of Eye Protection

Statistics or Facts About Eye Injuries in Workplaces

Every day, about 2,000 U.S. workers sustain job-related eye injuries that require medical treatment, according to the National Institute for Occupational Safety and Health (NIOSH). These injuries not only cause pain and suffering but can also lead to significant financial costs and productivity losses for businesses.

Regulatory Requirements and Standards for Eye Protection

Occupational safety standards, such as those set by the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI), mandate the use of appropriate eye protection in environments where eye hazards exist. Compliance with these standards helps ensure that eye wear is sufficiently protective, tested for specific conditions, and marked for quality assurance.

Overview of View3000 Anti-Scratch Goggles

Description of View3000 Goggles and Their Primary Use Cases

The View3000 Anti-Scratch Goggles are designed for a range of industries that require robust eye protection. Key areas of application include:

- Automobile: Protecting against sparks and metal filings.

- Construction: Guarding against dust and flying particles.

- Food: Ensuring hygiene and protecting against splashes.

- Oil and Gas: Shielding eyes from chemical splashes and debris.

- Manufacturing: Defending against a spectrum of mechanical hazards.

Materials Used and Design Features That Enhance Durability and Comfort

These goggles are crafted from polycarbonate, a material known for its toughness, which contributes to the goggles’ durability and resistance to impact. The lightweight design, at only 46g, along with features like a soft, adjustable strap and a contoured fit, ensure comfort even with extended wear, reducing wearer fatigue.

Key Features of View3000 Goggles

Anti-scratch Coating: How It Enhances Longevity and Visibility

The anti-scratch coating on the View3000 goggles is a critical feature that preserves the clarity of the lens over time. This coating prevents minor scratches that can accumulate from regular use, thereby maintaining visibility and extending the life of the goggles.

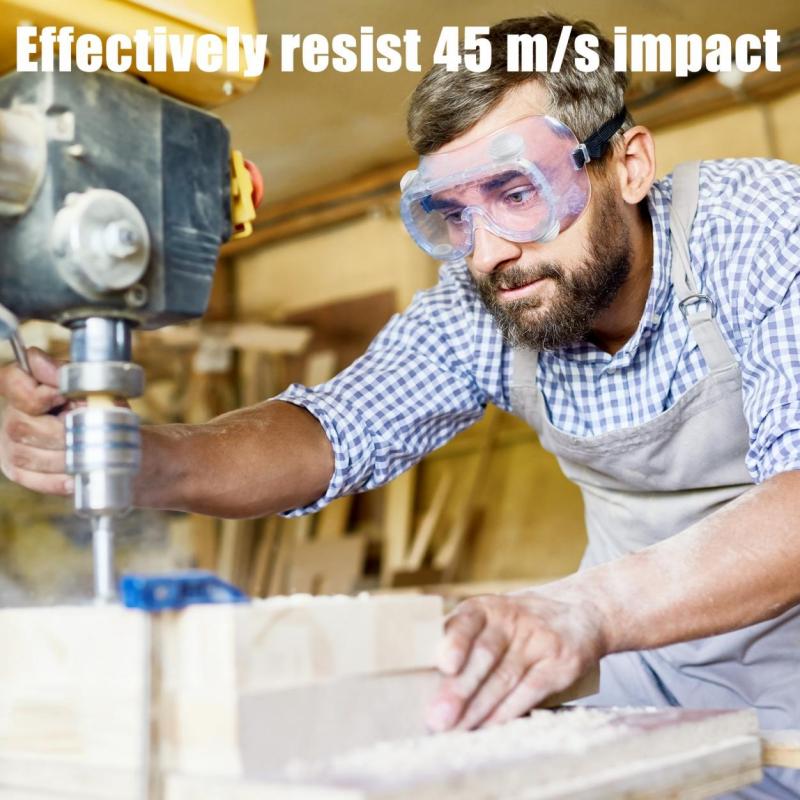

Impact Resistance: Protection Against High-Velocity Impacts

Constructed to meet rigorous safety standards, these goggles can withstand high-velocity impacts from flying debris and particles, making them suitable for high-risk environments. This level of protection is vital for preventing serious eye injuries.

Comfortable Fit: Adjustable Straps and Ergonomic Design

The adjustable straps and ergonomic design of the View3000 goggles ensure a secure and comfortable fit for a variety of face shapes and sizes. This adaptability is crucial in industrial settings, where workers need reliable protection without compromise to comfort.

Lens Options: Clear, Tinted, or Prescription Lenses Available

To cater to different working conditions and user needs, the View3000 goggles are available with various lens options:

- Clear lenses: For general indoor work with adequate lighting.

- Tinted lenses: For outdoor use or in bright environments to reduce glare.

- Prescription lenses: For workers who require corrective lenses integrated into their protective gear.

These features make the View3000 Anti-Scratch Goggles a versatile and essential safety tool in many industrial applications, providing both protection and comfort to the wearer.

Applications and Industries

Industries Where View3000 Goggles are Essential

The View3000 Anti-Scratch Goggles are indispensable in industries that demand stringent eye protection measures. These industries include:

- Construction: Where workers are exposed to risks from dust, debris, and flying particles.

- Chemical Industry: To shield eyes from harmful chemical splashes and vapors.

- Machinery Manufacturing: Where there’s a constant threat from sparks, metal filings, and sharp objects.

Specific Use Cases and Testimonials from Users in Different Sectors

Users across various sectors have praised the View3000 goggles for their reliability and protective features. In construction, workers note the goggles’ ability to keep dust and particles at bay, while in the chemical industry, the goggles are valued for their resistance to corrosion and chemical exposure. Machinery manufacturers appreciate the anti-scratch properties, which maintain clear visibility during operations involving metal work.

Maintenance and Care Tips

Guidelines for Cleaning and Storing View3000 Goggles

To maintain the effectiveness of the View3000 goggles, it is essential to clean them regularly with mild soap and lukewarm water, avoiding abrasive cleaners that could damage the anti-scratch coating. After cleaning, the goggles should be air-dried or gently dried with a soft cloth. For storage, keep the goggles in a clean, dry place away from direct sunlight or extreme temperatures to prevent material degradation.

Importance of Regular Inspections and Replacements

Regular inspections of the goggles for any signs of wear and tear such as scratches, cracks, or loose fittings are crucial. If damage is observed, replacing the goggles is recommended to ensure maximum protection. Regular replacement not only maintains protection but also ensures compliance with safety standards.

Compliance and Standards

Compliance with Industry Standards

The View3000 goggles comply with the Chinese national standard GB 14866-2006, which specifies the basic requirements for protective eye and face protection. This standard ensures that the goggles meet specific criteria for optical quality and resistance to impact, ensuring safety and reliability in hazardous work environments.

Certifications and Testing Methods for View3000 Goggles

The View3000 goggles undergo rigorous testing methods to certify their durability and safety. These tests include impact resistance tests to assess their ability to withstand high-speed particles, and scratch resistance tests to evaluate the effectiveness of the anti-scratch coating. These certifications reinforce the goggles’ suitability for use in tough industrial conditions.

Customer Satisfaction and Reviews

Feedback from Users on the Effectiveness and Comfort of View3000 Goggles

Users consistently praise the View3000 Anti-Scratch Goggles for their comfort and effectiveness. Construction workers appreciate the lightweight design that reduces strain during long shifts, while chemical industry professionals commend the goggles’ durability against corrosive substances. One user noted, “These goggles have been a game-changer on our construction site. They fit well, don’t fog up, and I feel secure knowing my eyes are protected.”

Another user from the manufacturing sector stated, “I’ve tried various goggles, but the View3000 stands out for its clarity and durability. It’s become my go-to choice for all tasks requiring eye protection.” These testimonials underline the reliability and comfort of the goggles in practical applications. Reinforcing its position as the security solution of choice across industries.

Success Stories Showcasing Real-World Applications

Case studies from various industries underscore the practical benefits of the View3000 goggles. For example, a case study in the chemical industry showcased how the goggles protected workers from severe eye injuries during an accidental chemical splash. Another success story from the construction sector highlighted the goggles’ ability to prevent eye injuries from flying debris at a demolition site. These real-world examples illustrate the critical role of effective eye protection in maintaining safety standards across industries.

Final Words

The View3000 Anti-Scratch Goggles are trusted for superior eye protection in industries like construction, chemical processing, and machinery manufacturing. Meeting the stringent standards of GB 14866-2006, these goggles excel in resisting impacts and scratches, ensuring durability and clear vision. Their lightweight, ergonomic design guarantees comfort during prolonged use, making them highly favored among professionals. Endorsed by positive user feedback and robust certifications, the View3000 goggles are a dependable safety essential, effectively safeguarding workers’ vision in challenging environments. Their proven performance across diverse applications solidifies their role as indispensable personal protective equipment worldwide.